Machine Design

In the modern industrial and manufacturing world, many facilities still employ personnel to perform repetitive, mundane tasks. Different operators can oftentimes equate to inconsistent production. In some cases, a single operator knows the process, and when they are absent, it creates a deficit in production. There are many machines that require manual processes that can often be hazardous, creating a risk to the operator. While there is value in some manually operated machines, there is a balance between risk management and process improvement that can be achieved.

While HCS specializes in electrical, electronic, and software design, we partner with highly reputable and experienced mechanical engineers and fabricators to complete an entire project. We have a network of partnerships with companies specializing in parallel fields carefully crafted through many years of successful installations.

Many customers have a concept for a new process, or an idea to improve a process but need assistance in bringing their idea to life. HCS can design, build, install, and commission a custom automated machine to perform the task. From the early design phase and onward, we will work with the customer and our partnering companies to ensure that all of the defined specifications are met and the project is a success.

However, Custom machines are not the only way to improve a process. Through system integration, HCS can take an existing machine and incorporate it into production flow. This can remove the need for additional operators by combining two or more processes into one, streamlining production from a single controller, therefore only requiring a single operator.

Contact Hagood Control Systems today to learn how a custom Hagood machine can greatly enhance your manufacturing or industrial processes!

Calendering Line Designed with Mechanical Partners for CSI Calendering LLC.

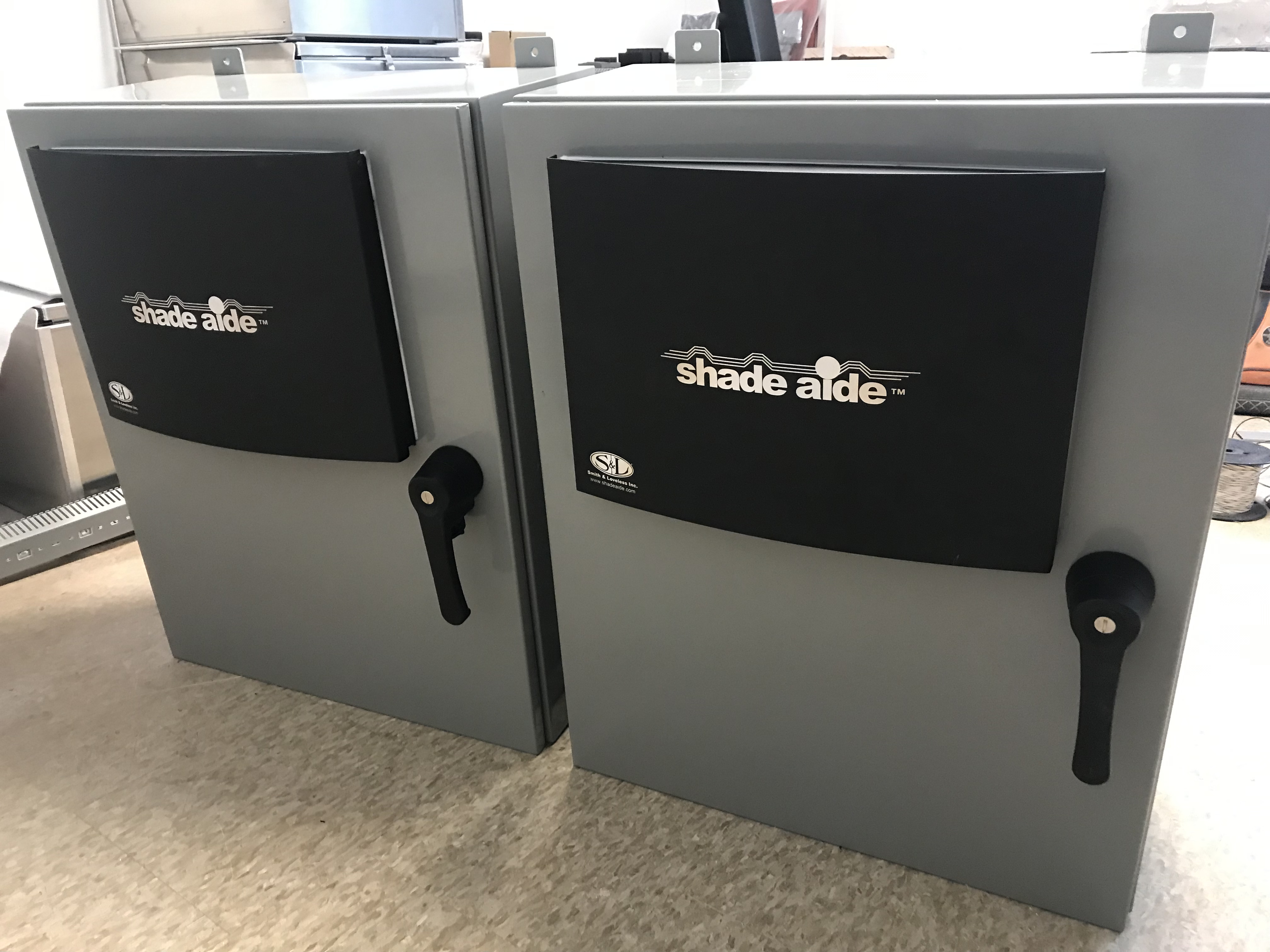

Custom panel build

Custom panel enclosure built for an oil field client